Artillery Shell Production – Shift Work

Russia is running its munitions factories 24/7, with multiple shifts. The US and Europe are not running multiple shifts, and they are not working 24/7. This isn’t necessarily laziness. In part, it’s a reluctance to shift to a “war economy.” Arguably, Russia is not a “war economy” either even though it is running its factories 24/7. It’s not a war economy because it isn’t one hundred percent mobilized. The only economy that is a “war economy” is Ukraine, because what little industry it has left is at maximum capacity and it is mobilizing everyone it can for the military.

The US is producing about 1,200 shells per day. Europe is producing 1,300 per day, for a total of 2,500 per day, or 912,500 per year. Russia is producing between 3 million and 5 million shells per year. At the lower end, the difference can be attributed to the difference between three shifts a day versus one. At the high end, which is probably more accurate, there are additional factors, like more plant and equipment, and more raw materials. None of those numbers take into account that a) Russia can always buy more artillery shells from North Korea, and b) China recently switched from 152mm caliber to 155mm. That means it has an enormous stockpile of 152mm shells to give Russia.

Either way, it is clear that, at current production levels, the US and Europe cannot keep Ukraine adequately supplied.

We have to do better. We should immediately move to 24/7 production and multiple shifts.

But can we?

Artillery Shell Production – Supply Chain

It’s not simply a matter of working longer hours. The artillery production supply chain plays a role.

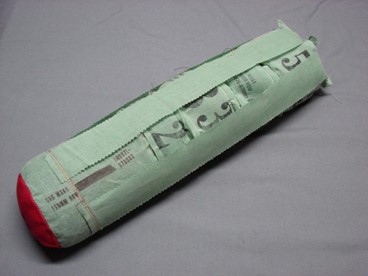

Let’s look at a regular 155mm artillery shell. There are three main parts: 1) The metal case, 2) the explosive – TNT, 3) the propellant (gunpowder). Figure 1 shows racks of 155mm artillery shells.

We need all three to send a shell downrange. And we have problems with all three.

Shell Casings

This is probably the easiest component to manufacture. The US has been ramping up its production of shell casings domestically and overseas. In 2023, the Defense Department awarded General Dynamics a $217 million order to increase its 155mm shell production at its Scranton, Pennsylvania and Wilkes-Barr plants. They expect to ramp up significantly the production of 155mm shell parts by 2025. To do this, they will have to overcome quality control problems. Manufacturing defects that result in cracked shell casings and other issues have repeatedly resulted in production setbacks.

Figure 2 shows 155mm artillery shell casings. Note that production is not complete. The factory only produces the casing. The casings are shipped to another facility in Iowa, where they are filled with TNT or IMX-101 and have fuzes installed.

Explosive – TNT or IMX-101?

The explosive of choice for artillery ammunition has been trinitrotoluene (TNT). TNT is more stable than dynamite, and it can be melted down and used to fill shell casings. The problem is that while it is more stable than dynamite, it’s not perfectly stable. Accidents caused by sympathetic detonation have killed soldiers and have been attributed to TNT instability. On top of that, TNT is toxic and harmful to the environment.

That set the army on course to find a “safe” substitute for TNT. Beginning in 2010, the US Army worked with BAE Systems on a new explosive for artillery shells. In 2013, the Army issued a $780 million order for BAE Systems to produce IMX-101 (Insensitive Munitions eXplosive-101) out of the Holston Army Munitions Plant in Holston, Tennessee.

Given the intention to switch artillery production to IMX-101, the US and Europe shut down all their TNT manufacturing plants. Today, there is only one TNT manufacturing plant – it’s in Poland. It produces 10,000 tons of TNT per year – enough for 1 million 155mm artillery shells. Remember that number. If we don’t ramp up IMX-101, we only have enough TNT in the US and Europe for 1 million shells per year (a bit over 2,500 per day). Russia makes 5 million.

Which would be a non-issue if tons of IMX-101 were being cranked out. They are not. In fact, the IMX-101 plant in Holston has not yet come up to speed. The original contract was issued in 2013, so it’s ten years behind schedule. While some IMX-101 is being produced, production has not been enough to replace the TNT foregone, and the cost per shell is 28% higher than TNT. The Holston plant requires considerable modernization and in 2023, the Army gave BAE Systems another $8.8 billion contract to upgrade the decrepit Holston facilities. The contract runs for another 10 years.

Propellant – Gunpowder

Gunpowder, invented in the 9th century by the Chinese, is used to send shells downrange. BAE Systems was selected in 2011 to upgrade the Radford, Virginia, gunpowder plant. Originally budgeted at $245 million in 2015, it’s now costing $399 million – over budget, 10 years behind schedule, and mired in litigation. The Army is relying on older plants. Unfortunately, these plants rely on foreign sources to supply the precursors to nitrocellulose and gunpowder. These materials are sourced from India and China. Figure 4 shows a bag of artillery propellant.

Summary

All the optimistic projections provided by US and European administrations have to be taken with a grain of salt. Claims that Europe is surpassing the US in shell production are also questionable. Europe is falling short of its commitment to Ukraine.

Of the three components needed for artillery shell production, it appears to this writer that the explosive (TNT vs. IMX-101) is the main constraint. Reliance on one plant in Poland that only produces enough TNT for one million shells a year is unacceptable. Remember the US and Europe are operating single shifts while Russia runs 24/7. One million shells a year on one shift is all the TNT that Polish plant makes.

We have to bite the bullet and reopen TNT plants everywhere. Right now, we couldn’t operate three shifts 24/7 even if we wanted to. We don’t have enough ingredients to make the product.

Cameron Curtis has spent thirty years on trade floors as a trader and risk manager. He was on the trade floor when Saddam’s tanks rolled into Kuwait, when the air wars opened over Baghdad and Belgrade, and when the financial crisis swallowed the world. Having written fiction as a child, he is the author of the Breed action thriller series, available on Amazon.

Check out his new Breed thriller, BLOOD SPORT, here:

https://www.amazon.com/dp/B0D6RC5V4V

See all the books in the series here:

—

Disclaimer: SOFREP utilizes AI for image generation and article research. Occasionally, it’s like handing a chimpanzee the keys to your liquor cabinet. It’s not always perfect and if a mistake is made, we own up to it full stop. In a world where information comes at us in tidal waves, it is an important tool that helps us sift through the brass for live rounds.

COMMENTS