The United States military is currently amid a transitional phase, reducing the emphasis we’ve placed on anti-insurgency and hunting terrorists in favor of preparing for the possibility of “near-peer” level opponents such as China and Russia. The problem is, transitions take time – especially for a military continuously hindered by defense contractors prioritizing profits over production, and by the grudgingly slow pace of approval for defense related acquisitions.

Our system, as it stands, can be heralded or derided depending on perspective: The F-35 Joint Strike Fighter and the new Gerald R. Ford class of aircraft carriers, for instance, are both examples of incredible technological achievements and horrendous spending practices run amok. Our nation will likely benefit from their development, but we can only afford to issue so many multi-billion dollar contracts without any incentive to come in under cost or on time. In order to make the shift we need, a concerted effort must be placed on keeping costs, and timelines, as small as possible – so there’s enough time and money to accomplish what we must in order to ensure our national security.

Engineers at the Naval Air Warfare Center Weapons Division (NAWCWD) in China Lake, California seem to have been working with just such a mindset, designing and testing a new ram jet missile system in just six months, using products they were able to purchase off the shelf with credit cards, rather than waiting months for sourcing bids and pricey supply contracts. Their methodology resulted in a price tag low enough for them to plan on repeated failures during their testing process – and by alleviating their fear of failure, it would seem these engineers managed to accomplish something incredible.

“If you have a small team, you can just get together and draw on a whiteboard on the fly and not have to worry about getting the large team involved and buy-in from everyone,” said Matt Walker, the head of the Airbreathing Propulsion Section at NAWCWD. He and his team converted the concept of ramjet propulsion, which was originally conceived nearly ninety years ago, into a cost and combat effective missile platform that may even outperform its more expensive contemporaries.

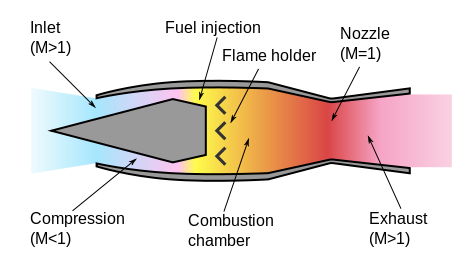

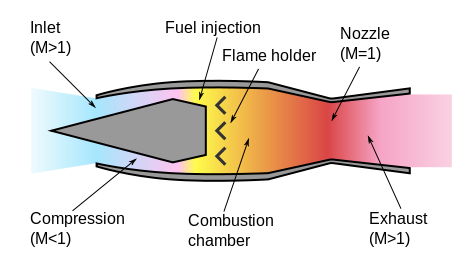

The ramjet propulsion system works in a different way than most modern missiles, which rely on an internal compressor to press air into their engines. Instead, ramjet systems use an opening at the front of the missile to allow air to be forced into the engine as the missile moves – a method which is lighter, more cost-effective, and far more efficient than engines that utilize a compressor. The problem is, ramjets can’t get moving from a stop, as they require airflow to function – leaving the ramjet design fairly useless for most applications.

To combat that, NAWCWD’s engineers purchased a $900 model rocket engine with a credit card, and mounted it on the missile as a secondary stage. The low price tag that resulted in using off the shelf rocket technology meant the engineering team could afford to try a number of variations on the design, allowing for failed attempt after failed attempt until they produced something truly useful.

The ramjet design utilizes simpler technology than current missile platforms, meaning it is less likely to suffer a mechanical failure. It can also propel a missile to speeds in excess of Mach 6 and can travel as much as three times as far as traditional missiles using the same amount of fuel. These improvements allow for faster missiles that offer our opponents less time to react and can be fired from further distances.

All in all, the team was able to produce a functional missile design in only six months, and for a fraction of the cost of other military projects, but they aren’t done yet. Now that the team at NAWCWD has proven their design to be viable, they are now working to improve it further, in order to make it even more useful for American war fighters in the years to come.

Among the planned modifications are integrating the rocket engine into a single missile body, rather than as a separate stage like in the current model, and continuing to perfect the propulsion system to pull as much speed and fuel efficiency out of the century-old theory as possible.

The team believes they will have a fieldable missile system that could see combat in as little as three or four years – with a price tag and a timeline that puts most such developmental projects to shame.

Already have an account? Sign In

Two ways to continue to read this article.

Subscribe

$1.99

every 4 weeks

- Unlimited access to all articles

- Support independent journalism

- Ad-free reading experience

Subscribe Now

Recurring Monthly. Cancel Anytime.

COMMENTS